- Shop All Welding Machines

- TIG Welders

- MIG Welders

- Plasma Cutters

- Multi-Process Welders

- Shop All Welding Gas

- 100% Argon Tank

- 75% Argon 25% CO2 Tank

- Shop All Welding Accessories

- Foot Pedals

- Guides & Regulators

- Machine Covers

- Torches & Guns

- Protective Gear

- MIG Welding

- TIG Welding

- Plasma Cutting

- Multi-Process Welding

- Welding Coupons

- Shop All Consumables

- CUT60 Ipt60 & Ipt40

- Cut50d & Ct520d SG-55

- Cut50dp & Ct520dp AG-60

- Tungsten Electrodes

- Collet Body 17/18/26 or 9/20

- Kits, Cups, Electrodes, Gas Lens, Collets

- Fixture Table

16+ Garage and Workshop Plans & Ideas

In the world of garage and workshop setups, efficiency and creativity go hand in hand. In this article, we'll explore a variety of carefully crafted spaces, each designed to suit the specific needs of enthusiasts and pros alike. These layouts provide inspiration and practical tips for turning your workspace into a productive and creative hub.

Jump to a section: Welding | Automotive/Garage | Woodworking | Gardening and Landscaping | General Home Repair | Organization/Storage

Welding Workshop Layouts

Explore effective arrangements of tools and equipment for creating a safe and efficient welding environment, and discover how to adapt these layouts for mobile welding rigs to take your welding projects on the go.

Welding Garage Workshop Layout

This garage layout is unique and efficient because it's divided into a clean side and a dirty side, with a clear central workspace. It also features ample electrical outlets, wall-mounted storage solutions, and an external air compressor with plumbed airlines, ensuring a well-organized and functional workspace for various projects.

Very Basic Mobile Welding Station

Valuable insights for starting a welding business with minimal tools and costs. It presents the importance of essential equipment like a welding machine, truck, bottles, hoses, a chop saw, and a MIG welder.

Mobile Welding Rig

An in-depth tour of a meticulously organized mobile welding rig owned by Meltin’ Metal Anthony. Throughout the video, Anthony showcases his well-equipped setup, including welding tools, equipment, and storage solutions, offering valuable insights and practical tips for fellow welders seeking to optimize their own mobile welding setups.

Fully Loaded Mobile Welding Rig

The 2017 Dodge Ram 4500 features three sturdy stainless steel boxes for storage, a 5,000-pound capacity crane, and an air pack-equipped Miller Trailblazer 302 welding machine. The rig's well-thought-out organization, custom-built features like the elevated welding machine, and the owner's attention to detail make it an impressive and efficient mobile welding setup.

Home Blacksmith Forge Workshop

Here’s an efficient and space-saving design, allowing designer Anne to set up a fully functional blacksmith and welding shop in a one-car garage. With the help of her friend Adam from Maker Table, they optimized the layout, incorporated a versatile welding fixture table, and created a compact yet highly functional workspace for metal fabrication. This setup demonstrates how you can transform a limited space into a well-organized and productive workshop, making it ideal for DIY enthusiasts and small-scale welding projects.

Auto Repair Garage Layouts

Discover the best layouts for automotive enthusiasts and professionals to efficiently tackle vehicle repairs.

Small Auto Shop Garage Tour

This shop features a well-organized and efficiently designed workspace. It includes an insulated garage with heating, cooling, and insulation to ensure a comfortable working environment throughout the year. The garage boasts a sub-panel for ample electrical supply, an extensive lighting setup, and a practical air compressor setup. Additionally, there's a variety of storage solutions, major tools such as a scissor lift, milling machine, welder, drill press, and lathe, making it a comprehensive and highly functional workshop for automotive and fabrication work.

Standard One-Car Beginner Mechanic's Garage

Distinguished by its well-lit and organized space, featuring LED lighting for better visibility and a comfortable environment with a mini-fridge, fan, and Bluetooth stereo. It boasts efficient storage solutions, essential workshop tools, and potential for a car lift system, making it an ideal workspace for automotive enthusiasts seeking both functionality and comfort.

2 Door Garage Auto Hobby Shop

[Photo by: Morton Buildings ] Link: 2 Door Garage Auto Hobby Shop

This automotive repair garage layout is designed to optimize space and functionality. By positioning workspaces along the walls, it reduces the risk of vehicle damage during storage and maintains an open, efficient atmosphere even with two vehicles in the shop. With additional height and raised trusses, it allows for adequate clearance when using vehicle lifts. The vertical or high track overhead door not only maintains a spacious feel when open but also provides extra lift clearance. An engineered end wall enhances the layout by offering loft storage options, maximizing the use of available space within the garage.

Professional Home Auto Repair Shop Layout

This video showcases a one-year transformation of a backyard garage from a beat-up and inefficient space into a well-organized, fully functional workshop. It highlights the process of renovating and improving the garage, including adding new lighting, a metal shed, a vinyl baseboard trim to protect the walls, and reconfiguring the layout to optimize space. It serves as an inspiring example of how to make the most of what you have and create an efficient workspace without the need for expensive equipment.

Home Garage for Auto Enthusiast

[Photo by: Blythe Building Company ]

Link: Home Garage for Auto Enthusiast

Standing out for its dedication to creating the ultimate car enthusiast's haven at home, this layout features a 4-car garage with a home car lift, reinforced concrete floor, insulated doors and walls, a vaulted ceiling for ample space, climate control, a beautiful epoxy-coated floor, and a well-equipped garage office, making it a dream space for car enthusiasts to work comfortably and efficiently while surrounded by their prized vehicles and tools.

Woodworking Workshops

Below are woodworking shop layouts that maximize creativity and functionality for crafting fine wooden projects in a variety of garage sizes.

Single-Car Garage Woodshop

[Photo by: Wood Magazine ]

Link: Single-Car Garage Woodshop

This layout is unique because it maximizes the use of a compact 15 x 22' space to create a full-featured woodworking shop. It incorporates major tools, ample storage, and a dust-collection system while maintaining mobility and affordability. The consistency in design and use of readily available materials like MDF, plywood, and soft maple make it a high-functioning shop on a low budget.

Two-Car Garage With Car Woodworking Workshop

[Photo by: The Power Tool Website ]

Link: Two-Car Garage With Car Woodworking Workshop

This shop layout is versatile, a design that maximizes space for woodworking while accommodating a 220-volt panel for powering tools and a hanging electric heater. It also features clever storage solutions like wood shelves, drawers, and cabinets integrated into workbenches, offering efficient organization for various tools and equipment, making it a well-organized and functional woodworking space within a 2-car garage.

Gardening and Landscaping Work Spaces

Find inspiration on how to set up workspaces tailored to gardening and landscaping tasks for a beautiful outdoor space.

Potting Shed or Greenhouse Setup

[Photo by: Waltons ]

Link: Potting Shed or Greenhouse Setup

Update your greenhouse with clever organization tips: Create plant zones, use versatile shelving for vertical space, and repurpose everyday items for efficient storage. Maximize productivity and keep your greenhouse tidy.

Portable Garden Tool Cart for Small Spaces

Transforming plywood scraps into a versatile garden tool storage cart, this unique project offers scalability to accommodate various tool collections. With meticulous attention to detail, the builder uses a table saw, Forstner bit, router, and more, ensuring a well-organized and efficient gardening setup. Discover precise measurements and expert craftsmanship in this engaging DIY guide.

General Home Repair Workshops

Find what works best for you with these versatile layouts that accommodate various home repair and maintenance projects.

One-Car Garage Multifunctional Workshop

[Photo by: Bench Top Wood Works ]

Link: One-Car Garage Multifunctional Workshop

Discover a unique home repair shop layout designed for maximum efficiency and mobility within a single-car garage bay. This innovative setup combines shared power and dust collection, modular flexibility, and smart organization principles to create a versatile workspace that adapts effortlessly.

Cellar Home Repair Hub

[Photo from: Bob Vila by woodgears.ca ]

Link: Cellar Home Repair Hub

Turn your cellar into a unique and practical workshop space with these top tips. Learn the advantages of a basement workshop, from the built-in heating to soundproofing benefits, and learn how to optimize your workspace for heavy tools while addressing common challenges like dampness and access.

Organization and Storage Layouts

Tips on organizing tools and materials to maintain a tidy and efficient workshop environment.

Compact Tool Storage and Organization

Transform your small workshop with this unique multi-layer storage system, featuring rolling backboards that maximize space efficiency. With custom tool holders and clever design, this project creates efficient storage for your tools and easy access, making the most of your limited space. Join the journey of optimizing your small shop with this innovative home repair shop layout.

French Cleat Wall System in a Small Workspace

Sources: Featured Image courtesy of Andrea Piacquadio

Thanks for reading.

Leave a comment 0 comments, be the first.

Please note comments must be approved before they are published.

0 Items in your cart

Subtotal $0

Tax and shipping will be calculated at checkout.

Your shopping cart is empty.

Your cart is empty

Have an account?

Log in to check out faster.

You are $99.00 away from free shipping

Current Promotions 💰

MIG Welding

Tig welding, stick welding, multiprocess welding, engine drive welding, cutting tools, plasma cutting, plasma consumables, torch cutting, protective gear, welding helmets, helmet lenses, plates & accessories, personal safety, fire, spark & fume protection, grinding and metalworking, power tools, abrasive & polishing, cordless tools, power tool accessories, shop by brand, shop all brands, manufacturer savings promotions, baker's exclusive promotions.

Weld My World - Welding News

How to Design your Welding Shop

If you have the advantage of designing your welding shop before anything is in it – you’ll be able to design a smooth-running, functional, and efficient place. Choose the right equipment and layout and you’ll save energy costs, increase space, and provide a more ergonomic and pleasant place.

Space vs. Efficiency

Consider the space of individual booths within your welding shop. There should be ample room for comfortable work and room for supervisors and others to pass through the area. Finding the right balance between spaciousness and space-efficiency may be tricky.

If the shop is very large overall, you may have wasted walking time between stations. Too small and there will be no room to pass from work tables, to welding booths, to cutters, grinders, hydraulic presses and cooling tanks. If welders have to work in cramped quarters you may suffer occasional collisions between welders and/or equipment. Consider too, if equipment needs to be replaced, will you need to move several booths or welders to get old/faulty pieces of equipment out?

Applying ergonomic principles to welding reduces space and proximity issues while decreasing likelihood of injury. A streamlined and comfortable environment leads to logical work flow and efficiency. Many experts recommend a booth size of 7×10 feet to accommodate worker and occasional visitor or helper.

In cramped spaces – choose your equipment very carefully. A tight floor plan means equipment with a smaller footprint may be well warranted. An inverter, for example, takes up 20% less space than a rectifier type unit.

Your Shop on Paper

An architect can provide you with an initial drawing for the shop layout. Use a copy of the cut-to-scale drawings to sketch in people. Mentally walk through activities and imagine people in the space and how they will use it. Doing so will help you design a space optimized for productivity and efficiency.

Once the primary welders and equipment are drawn in, consider the additional tools needed to perform each task. Add space for storage of supplies and personal protective equipment. Take note of walking distance to these places in relation to the frequency of which they will need to be visited. It may seem insignificant, but if you have to make trips from one end of the shop to the other, multiple times in an eight hour day, those trips add up!

And don’t forget cutting stations and other work areas. Grinders that have their own booth will reduce noise and mess. Weigh the cost of equipment in relation to how it will be used, if it will save time, travel, and/or space. Don’t forget to consider storage of welding gases, fume extraction, and cleaning.

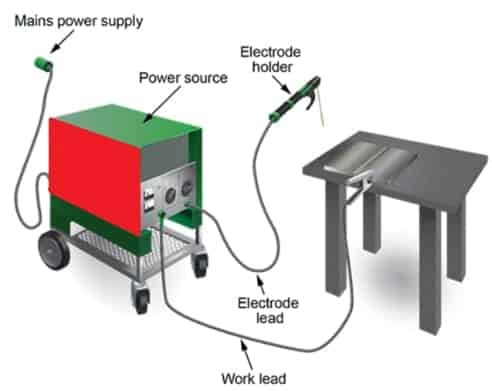

Electricity

You’ll likely need to consult with an electrician to discuss service to the shop. Multiple power sources should be written into the plan. Electricity is one of the largest expenses in a welding shop. Select a power option in terms of volts and amps that will support the number of welders, cutting machines, grinders, and presses that will be used. Prices and efficiencies should be weighted. The exterior wall is prime real estate for electrical service, so keep that in mind when laying out booths and equipment. Make sure the architect is aware of this, and the room needed for the main power box and individual circuit breakers.

Do you have the option of a main gas manifold system? This would allow drops to each welding station and cutting location. Consider which gases will be used where. You’ll want to consider acetylene, oxygen, argon, CO2, water, compressed air. Lines need to be adequately spaced and room needs to be allowed for servicing flow meters and regulators.

Fume extraction should take place from each individual booth. A flexible hood will allow positioning directly over the work to remove fumes. Heavier-than-air gasses like argon and CO2 should be collected close to the floor. A third level of extraction would be near the ceiling to remove the higher fumes. Vaporized metal fumes would be extracted from downdraft tables at the plasma arc cutting machines.

Take the time to design your welding shop before anything is in it – you’ll be able to design a smooth-running, functional, and efficient place. If your shop is already running, consider which steps you can implement to improve the current layout. When you need to replace equipment, choose the right equipment. Wise choices in equipment and layout result in reduced energy costs, increased space, and provide a more ergonomic and pleasant place.

Welding Supplies for your Welding Shop

When you're ready to supply your new welding shop, or upgrade your existing one, give Baker's Gas & Welding Supplies a chance to earn your business!

Leave a comment

Please note, comments need to be approved before they are published.

Weld My World – Blog By Baker’s Gas

View all >, how to weld aluminum: techniques and tips for success, what you need to weld at home: a comprehensive guide for safe and successful welding projects, how to determine which cga connection you need for acetylene tanks, unleash unmatched power and portability with the esab renegade volt battery-powered welder.

- Choosing a selection results in a full page refresh.

3X ENTRIES FROM NOW TO THE END 🔥 FINAL WEEKS OF MY FIRST EVER RAT ROD GIVEAWAY! GEAR UP WITH WELDERUP MERCH TODAY FOR A CHANCE TO WIN! 🔥

Country/region

- Australia AUD $

- Canada CAD $

- United States USD $

- Austria EUR €

- Belgium EUR €

- Croatia EUR €

- Denmark DKK kr.

- France EUR €

- Germany EUR €

- Gibraltar GBP £

- Ireland EUR €

- Israel ILS ₪

- Italy EUR €

- Netherlands EUR €

- Norway USD $

- Spain EUR €

- Sweden SEK kr

- Switzerland CHF CHF

Item added to your cart

View Shipping Policies

Please allow up to 14 days for the shipping and handling of your purchase. In many cases you will receive your purchase sooner. For international shipments, please allow up to to 24 days.

INTERNATIONAL SHIPMENTS MAY HAVE IMPORT DUTY AND HANDLING FEE CHARGES DUE UPON DELIVERY.

The CUSTOMER is responsible for these additional costs. We only ship to countries that allow us to track shipments.

RAT ROD MUSEUM TOURS

Explore the showroom floor and get up close and personal with our curated collection of rad rides. Explore the legendary vehicles from Discovery Channels Vegas Rat Rods.

Self-Guided Rat Rod Museum Tours

Experience Steve's distinctive brand of rat rod culture firsthand and at your convenience on a self-guided tour of the new WelderUp showroom and store. Inside, Steve has created the perfect setting to showcase his personal collection of rat rods as well as a few of the builds featured on Vegas Rat Rods . WelderUp is not your average car customization shop. Steve Darnell is the creative mastermind behind the motorized works of art that emerge from the WelderUp shop. Las Vegas is the perfect setting to inspire Steve to design the one-of-a-kind rat rods only he can create. Steve's incredible talent and mind-blowing creativity have caused a frenzy in the car world, landing Welder Up on the hit TV show Vegas Rat Rods, now airing on the Discovery Channel.

Admission $5.00 per person Free for children 12 and under

VIP Rat Rod Museum Tours With Steve

We are not currently offering any VIP tours. Inquire about large group options through our contact page.

MUSEUM HOURS

Monday 10am – 3pm Tuesday 10am – 3pm Wednesday 10am – 3pm Thursday 10am – 3pm Friday 10am – 3pm Saturday 10am – 3pm Sunday 10am – 3pm

Closed all Major Holidays

MUSEUM LOCATION

3160 S Highland Dr,Suite D Las Vegas, NV 89109

(702)862-4723

- Choosing a selection results in a full page refresh.

- Opens in a new window.

20 questions with answers for Welders: FAQS

Welding is a skilled trade that involves joining two or more metal pieces together using heat, pressure, or a filler material.

It is a critical process that is used in many industries, including construction, manufacturing, and repair and maintenance. To help you understand the basics of welding, we’ve put together a list of 20 questions and answers for welders.

What is welding?

- Welding is a process that joins two or more metal pieces by heating them to a high temperature and applying pressure or a filler material to fuse them together.

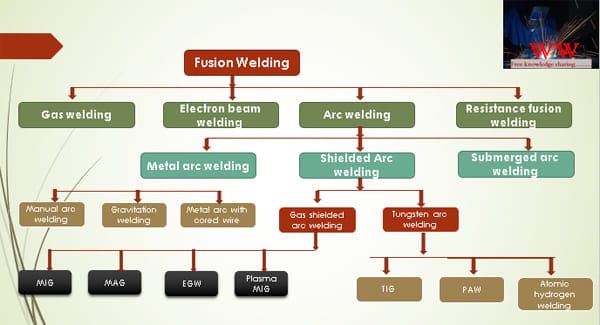

What are the different types of welding?

- There are several types of welding, including shielded metal arc welding (SMAW), gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), flux-cored arc welding (FCAW), and submerged arc welding (SAW).

What is SMAW welding?

- SMAW welding, also known as stick welding, is a manual welding process that uses a consumable electrode coated in flux to lay the weld.

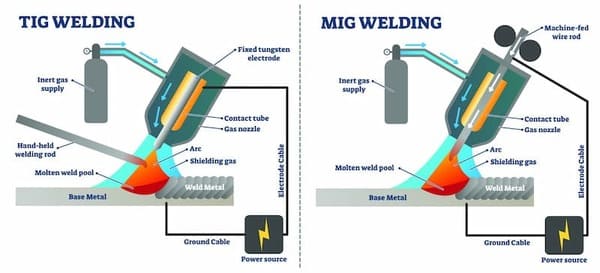

What is GTAW welding?

- GTAW welding, also known as TIG welding, is a manual welding process that uses a non-consumable tungsten electrode to produce the weld.

What is GMAW welding?

- GMAW welding, also known as MIG welding, is a semi-automatic or automatic welding process that uses a consumable wire electrode and a shielding gas to produce the weld.

What is FCAW welding?

- FCAW welding is a semi-automatic welding process that uses a flux-cored wire electrode and a shielding gas to produce the weld.

What is SAW welding?

- SAW welding, also known as submerged arc welding, is an automatic or semi-automatic welding process that uses a consumable electrode and a shielding powder to produce the weld.

What is the purpose of a filler material in welding?

- A filler material, also known as a welding rod or wire, is used to add material to the weld joint and help fuse the metal pieces together.

What is the difference between TIG and MIG welding?

- TIG welding uses a non-consumable tungsten electrode to produce the weld, while MIG welding uses a consumable wire electrode.

- TIG welding is typically used for more precise and delicate welding jobs, while MIG welding is more commonly used for larger and faster welding jobs.

Read more: TIG vs MIG Welding

What are the main safety precautions that a welder should take?

- Some of the main safety precautions that a welder should take include wearing personal protective equipment (PPE), such as a welding helmet, gloves, and protective clothing, and making sure to work in a well-ventilated area.

- It’s also important to always follow the manufacturer’s instructions and guidelines for the welding equipment and materials being used.

Read more: Complete list of Welder’s PPE.

What are the dangers of welding?

- Some of the dangers of welding include the risk of fire or explosion , the risk of inhaling dangerous fumes and gases, and the risk of electrical shock.

- Welders should always take the necessary safety precautions to protect themselves from these hazards.

What are the benefits of welding?

- Welding can provide many benefits, including the ability to create strong and permanent joints between metal pieces, the ability to repair or modify metal structures, and the ability to create custom metal pieces or products.

What are the qualifications needed to become a welder?

- The qualifications needed to become a welder can vary depending on the type of welding and the employer’s requirements. However, most welders will typically need to have a high school diploma or equivalent and will need to complete an apprenticeship or vocational training program.

Read more: How to be a Certified Welder?

How can I improve my welding skills?

- To improve your welding skills, you can practice welding on different types of metal and thicknesses, learn about different welding techniques and processes, and take welding classes or workshops.

What are the differences between welding mild steel and stainless steel?

- Welding mild steel and stainless steel are different as stainless steel has a higher nickel and chrome content, which requires different welding techniques, filler metals, and shielding gases.

How to select the right welding rod?

- To select the right welding rod, you need to consider the base metal you will be welding, the welding position, the welding amperage and the type of welding you will be doing.

Read more: Welding Rod Selection Chart.

How to prepare the surface before welding?

- To prepare the surface before welding, you need to clean the metal surface, remove any oil, rust, or paint, and make sure the metal is in the right position for welding.

What is the difference between AC and DC welding?

- AC welding uses alternating current to produce the weld, while DC welding uses direct current to produce the weld. DC welding is typically used for welding mild steel and stainless steel, while AC welding is typically used for welding aluminum.

Read more: AC vs DC Welding

What is the difference between welding and brazing?

- Welding and brazing are both methods of joining metal pieces, but they use different techniques and materials. Welding melts the metal pieces together, while brazing uses a separate filler metal to join the pieces.

Read more: Welding vs Soldering vs Brazing

What is the difference between welding and soldering?

- Welding and soldering are both methods of joining metal pieces, but they use different techniques and materials. Welding melts the metal pieces together, while soldering uses a separate filler metal and a lower heat to join the pieces.

What are the common welding defects?

- Common welding defects include porosity, cracking, lack of fusion, and burn-through. These defects can occur due to improper technique, incorrect equipment settings, or poor quality materials.

Read more: Welding Defects types, their causes & prevention.

How to prevent welding defects?

- To prevent welding defects, it’s important to use the correct welding techniques, properly maintain and set up the welding equipment, and ensure that the materials being used are of good quality.

What is the difference between welding and adhesive bonding?

- Welding and adhesive bonding are both methods of joining metal pieces, but they use different techniques and materials. Welding melts the metal pieces together, while adhesive bonding uses a separate adhesive to join the pieces.

What is the difference between welding and riveting?

- Welding and riveting are both methods of joining metal pieces, but they use different techniques and materials. Welding melts the metal pieces together, while riveting uses a separate rivet and a tool to join the pieces.

What is the difference between welding and bolting?

- Welding and bolting are both methods of joining metal pieces, but they use different techniques and materials. Welding melts the metal pieces together, while bolting uses separate bolts and nuts to clamp the pieces together.

How to maintain welding equipment?

- To maintain welding equipment, it’s important to regularly clean and inspect the equipment, ensure that all connections are tight and secure, and replace any worn or damaged parts.

Related Posts:

Material Welding is run by highly experienced welding engineers, welding trainers & ASNT NDT Level III bloggers. We strive to provide most accurate and practical knowledge in welding, metallurgy, NDT and Engineering domains.

- The Fabricator

- Canadian Metalworking

- Our Publications

- E-Newsletter

- Digital Edition

- The Tube and Pipe Journal

- The Fabricator en Español

- Additive Manufacturing

- Aluminum Welding

- Arc Welding

- Assembly and Joining

- Automation and Robotics

- Bending and Forming

- Consumables

- Cutting and Weld Prep

- Electric Vehicles

- Hydroforming

- Laser Cutting

- Laser Welding

- Manufacturing Software

- Materials Handling

- Metals/Materials

- Oxyfuel Cutting

- Plasma Cutting

- Power Tools

- Punching and Other Holemaking

- Roll Forming

- Shop Management

- Testing and Measuring

- Tube and Pipe Fabrication

- Tube and Pipe Production

- Waterjet Cutting

Industry Directory

- Search the Directory (Showrooms)

- Buyers' Guides and Directories

- Product Showcases

- Classified Ads

- Register for the Directory

Our Affiliated Brands

- Fabricators and Manufacturers Association

- Nuts, Bolts & Thingamajigs Foundation

Account Login

- From The Fabricator

How to give new life to an old press brake

Robotic sanding and polishing, no CAD required

Submarine camp introduces kids to maritime fabrication

Cobot welding in high-product-mix manufacturing

- From The Welder

The MIG gun liners guide

Welding aluminum? Consider automation

Young welders showcase talents at Skills USA Championships

Young Utah welder to take part in WorldSkills welding competition

- From The Tube and Pipe Journal

Trusting good people to do their jobs in fabrication

Planning for and navigating growth in a small business

Combining inspection techniques to ensure quality tubing

Why is tube laser power not keeping pace with sheet lasers?

- From The Fabricator en Español

Alcanzando el éxito con el corte por plasma mecanizado

El futuro de la soldadura: Claves para adoptar la automatización con éxito

Conociendo el doblado con cobots

6 mitos sobre las herramientas de la prensa dobladora

How shops can succeed in the modern welding industry, the founder of industrial succession shares to grow a metal fab shop.

- By Jules Brenner

- November 14, 2023

Growth in the welding industry is not just about increasing profits. It's about creating a business model for your shop that is resilient, adaptable, and capable in today’s and tomorrow’s climate. Images: Industrial Succession

In today's evolving business landscape, achieving sustainable growth is not just an objective but a necessity, particularly in the welding industry. This sector, marked by its dynamic nature and the invaluable role it plays in various other industries, needs to adapt constantly and grow sustainably to remain competitive and profitable.

Growth is not just about increasing profits. It's about creating a business model that is resilient, adaptable, and capable of withstanding market fluctuations while maintaining its ability to respond to the evolving needs of clients and the industry. A focus on growth allows welding shops to optimize their resources, improve their processes, and better serve clients. By approaching growth from a sustainable perspective, welding businesses can ensure long-term viability where they're not only thriving but are well prepared for consistent future success. Embracing sustainability is about building a welding shop that is prepared to operate at a high level and meet the challenges of the present market.

Steps for Growing a Welding Operation

Relying on work to simply come to you without exerting deliberate effort is a risky approach that can stunt your business growth. Like any other, the welding industry is competitive and requires proactive strategies to stand out and attract business.

Consistently implementing and upgrading initiatives such as marketing, networking, and constantly delivering high-quality work is integral to your shop's growth. These efforts demonstrate initiative, bringing your business to the attention of potential clients faster than passive waiting ever could.

Here are some of the most important strategies to consider to ensure stable growth and competitive services.

Professionalizing Early. Embracing professionalism from the early stages of your welding shop operations is pivotal to growth and sustainability. By treating your shop as a business right from the start, you position your venture as a serious and credible entity in the market. This includes setting up proper management systems, instituting effective communication and marketing channels, and ensuring adherence to industry standards and regulations. Not only does this boost your reputation, but it also establishes trust among potential clients and sets the stage for acquiring high-profile clients down the road.

Professionalizing early is crucial for long-term sustainability. It provides a solid foundation for your business, helping it withstand market fluctuations and competition. By establishing strong management systems, consistent service delivery, and a solid brand presence from the outset, your shop is better positioned to seize early opportunities and gain important, early momentum for growth.

As you professionalize your operation, it is also important to be preemptive about the hurdles you may face and how to overcome them effectively. For this reason, it’s crucial to treat your business like a professional in the early days, as preparing for growth and anticipating hurdles can help you be better prepared to scale your operations and create more profit.

Diversifying Your Service Offerings. In the competitive world of welding, diversifying your service offerings is a key strategy for sustainable growth. Offering a wide range of services not only opens opportunities to attract different customer segments but also helps mitigate the risks associated with relying on a single revenue stream. If one service area experiences a slowdown, other areas can help keep the business buoyant. Market diversification is a powerful way to create a safety net for your welding shop and ensure its long-term success. To start diversifying, begin by evaluating the skill set of your team and your existing equipment. Identify untapped areas that align with your competencies. You may consider offering services such as custom metal fabrication, industrial welding, on-site welding, or marine welding, based on market demand and your team's expertise. Conduct market research to understand the needs and preferences of your potential clients. This can guide your decisions on the services to offer. Remember, quality should never be compromised for the sake of diversification. Training your team and investing in the right equipment gradually is crucial.

This transition is not merely about increasing your revenue or expanding the workforce. It's about broadening your range of services and becoming a one-stop solution for your customers. Offering more diverse services may help attract a wider client base consistently and demonstrate to clients that you are a top-of–the-class welding service. Additionally, it provides an opportunity to cross-sell your services, leading to increased customer retention and loyalty. Diversification is the essence of growth in many businesses, and welding shops are no exception.

To diversify your services, evaluate your shop’s skill sets and equipment. This could help in identifying areas and services you could provide now or in the future.

Embracing Digital Marketing. In today's digital age, understanding the power of social media and modern marketing strategies is crucial for your shop to grow sustainably. Social media platforms are bustling marketplaces that offer a direct line to your target customers if you use them correctly. Leveraging these platforms allows you to showcase your work, engage with potential clients, and even provide customer service in real time.

Modern marketing strategies—targeted digital advertising, search engine optimization, and content marketing—can significantly boost your online visibility, drive more traffic to your website, and convert visitors into customers.

Successful marketing is all about speaking to your customers' real-world needs. It's not about what you think they need; it's about understanding and addressing their genuine challenges. Remember, your shop is not just providing welding services; it's providing solutions to customer problems. Do your best to understand their requirements and communicate how your services can meet those needs and how your brand can represent this mission. This customer-centric approach, combined with an effective social media and branding strategy, will pave the path for sustainable growth.

Growing Sustainably. Sustainable growth is the key to building a successful welding shop. It's all about finding the perfect balance between expanding your business and maintaining high-quality output. The first step towards achieving this is to hire ahead of time to prepare for a steady increase in demand for services. Preparing employees to be ready to handle an increase in workload can help you maintain your velocity and readily scale your operations as needed.

It also is important to invest in skills development. This could mean enrolling your team in additional training courses or bringing in an expert to upskill your crew. The more skilled your team is, the greater your capacity for taking on larger or more specialized projects—potentially increasing your prospects for new revenue streams.

The importance of not rushing growth cannot be overstated. While it may be tempting to take on every possible job to increase your revenue quickly, this can lead to overextension and compromise the quality of your work. It’s crucial to remember that your welding reputation hinges on the quality of your workmanship. Therefore, growing your business has to be a calculated process, gauging your team's capacity and the complexity of the projects you undertake.

Steady revenue growth is another critical element of sustainable growth. Stable revenue generation allows your business to stay afloat, invest in new equipment or technologies, and expand your workforce when necessary. You must have a clear understanding of your shop's financial health, including your operating costs, profit margins, and cash flow. By carefully monitoring your finances and making informed decisions, you can foster sustainable growth in your welding shop.

Stake Your Claim in the Welding Industry

In the welding industry, securing a prominent space isn't a walk in the park. It requires strategic planning, consistent quality output, and an understanding of the market dynamics. This industry is fiercely competitive, with numerous players vying for the same opportunities. Therefore, it is crucial to differentiate your shop from the rest, not just in terms of the quality of work, but also in customer service, pricing, and after-sales support. Sourcing the right equipment, employing skilled labor, and developing unique marketing strategies can go a long way in making your mark in this industry.

Recognizing the competitive nature of the welding industry and adapting to it can be the difference between mere survival and thriving growth. In such a climate, the importance of professionalizing early cannot be overstated.

Professionalism will not only increase your customer base but also establish your brand's reputation in the market. This involves everything from maintaining high safety standards and providing excellent customer service to adopting advanced operational systems and practices. Adopting a professional outlook early in the business lifecycle can significantly boost your growth velocity and your chances of success.

Always remember that your shop’s reputation hinges on the quality of your workmanship—will your growth goals be hindered if there’s a dip in quality? Growth is a calculated process and should not be rushed.

Remember, it's not just about growth—it's about sustainable growth. Rather than focusing solely on short-term gains, strive to design a strategy that is built upon long-term stability and success. This can be achieved by regularly investing in staff training, implementing environmentally friendly practices, maintaining good client relations, and striving for continuous improvement.

Sustainable growth ensures your welding shop can weather economic downturns, respond to evolving industry trends, and maintain a reputable presence in the industry. By securing your space, recognizing competition, professionalizing early, and focusing on sustainable growth, your shop will be well positioned to find independent success in the welding industry.

Pictured is the staff of California-based Pendarvis Manufacturing, which is part of Industrial Succession.

About the Author

Jules Brenner

Industrial Succession Group

646-847-9963

See More by Jules Brenner

About the Publication

Read more from this issue

- View the Digital Edition

Subscribe to The Welder

Related Companies

- Pendarvis Manufacturing

subscribe now

The Welder, formerly known as Practical Welding Today, is a showcase of the real people who make the products we use and work with every day. This magazine has served the welding community in North America well for more than 20 years.

- Stay connected from anywhere

Easily access valuable industry resources now with full access to the digital edition of The Fabricator.

Easily access valuable industry resources now with full access to the digital edition of The Welder.

Easily access valuable industry resources now with full access to the digital edition of The Tube and Pipe Journal.

Easily access valuable industry resources now with full access to the digital edition of The Fabricator en Español.

Adam Fullerton is a Toronto-based metal fabricator who specializes in creating railings, doors, and other accent pieces for...

- Listen to the Podcast

- Trending Articles

Holston Gases transitions to third-generation family-owned business

Welding machine suitable for use by both new and expert welders

- Industry Events

NBT Awards Gala 2024

- October 2, 2024

- Mount Prospect, IL

Pipe and Tube Conference

- November 13 - 14, 2024

Welcome back!

Forgot password?

Not yet registered? Sign up

- My Showrooms

- My Saved Guide Comparisons

- Change Password

- Change Personal Info

How to Start a Lucrative Welding Business & Succeed

Last Updated on Jan 30 2023

Many people dream of owning their own successful company: making the income a successful business owner makes, working their own hours, and having the best team. Maybe you’re dreaming of this.

If you’re a welder, this may be the perfect option for you. The opportunities in the business climate around the world are incredible for those interested in taking the plunge, but there are some fundamental principles any aspiring company owner needs to learn first.

It’s not just learning how to start a welding business. That’s the easy part. It’s about how to establish a company that will succeed. Read this guide to starting a lucrative welding business with a mind to embrace the principles discussed, and you’ll know the steps to take for success.

Different Kinds of Welding Businesses

Before starting a business, it’s essential to figure out what kind of company you want to run. There are plenty of different routes to take, and they each have their own pros and cons. Reading this post, Top 10 Welding & Fabrication Business Ideas To Make A Profit , will give you a thorough guide to the different options available to you. Here are some good options to consider:

- Heavy stainless steel fabricating

- Aluminum welding

- Heavy haulage trailer manufacturing

- Steel construction fabricating

- Mobile welding service

- Underwater welding service

- Breakdown welding service

When to Start a Welding Business

The first step to consider is the timing of starting a business. Welding is a booming trade worldwide, and particularly in the U.S., so it’s not a matter of when to start market-wise. I’m convinced that whatever market you start in, these principles will help you succeed.

The crucial timing is determined by several factors that will be expounded upon below. First, are you ready with the right mindset? You may be an excellent welder and have a list of clients waiting to send work your way, but unless your business approach is correct, your company won’t succeed.

You also need to have your finances managed, and you must have the support of others to help you with your endeavors. You can start a business lacking in one of these areas, and it may still have some success. However, it cannot flourish to its full potential unless all three of these areas are taken care of.

The Right Mindset

Running a successful welding business needs much more than merely working in a workshop can produce. It requires three specific mindsets that will distinguish you as an acclaimed business owner, rather than a mediocre one.

Embrace a customer-focused mindset

You must have a customer-focused mindset. You need to understand your customers and dedicate yourself to providing the most satisfactory experience for them. This will result in your being willing to own their mistakes as your own, so they come away satisfied and enriched by your service. It will provide you with stable customer relationships, and in turn, they’ll support you with ongoing contracts.

If you choose to only look after the customers who you think will provide ongoing work, while neglecting others, you may not see the immediate consequences, but it will stunt the growth of your business. You’ll never know who the ordinary person is who turns up on your doorstep, and who they could recommend you to. Looking after everyone will do wonders for your company.

Embrace an employee-sensitive mindset

As crucial as a customer-focused mindset is, it’s not enough. You must also be committed to an employee-sensitive mindset, and in doing so, instill in them a customer-focused ethos. Remember that your employees will always be your business, and likewise, you control a massive part of their livelihood. If you’re unwilling to bear that responsibility, and only want to treat them as a means for your own success, you’ll inevitably have very little success.

The best way to treat employees is to think about being in their shoes. Treat them with the encouragement and support you would appreciate. The results will be tremendous for them and for you. Establish your mindset in this before starting a business. When life becomes hectic as your company starts growing, you’ll have the right thinking in place without trying to figure it out under pressure.

Learn your strengths and weaknesses

No one person is the superhero of a business. A business is always marked by a team and by people who excel in different areas. This is what makes successful businesses thrive. Be willing to learn where your strengths lie and what your weak areas are, so you can ensure your time is primarily spent on areas you’re best at. If you try to do everything, your company will be hindered significantly.

Without trusting different people to take care of critical roles, there will always be a lack of balance in your company, and you’ll lose on many necessary fronts. Learn your strengths and weaknesses by self-examination and asking others around you before you start your business, and you’ll have a stable foundation to build your company on.

It’s essential to have strong financials before starting a business. Although a broad base of cash is helpful and sometimes necessary, your financial management is most crucial. You can start a small business with a few dollars and scale it upwards with sound financial management, but it doesn’t work the other way around. If you have a large bank account without the necessary financial systems in place, your company will only last so long before closing in on itself financially.

If you’re not so good with finances, find someone to mentor you, or employ someone who excels financially to run that side of your business. The cost of hiring them will be tiny in comparison to the return they’ll produce for you.

The Support of Others

Employees are important to a business, but so is the support of outsiders like family, friends, and other business owners. The more people involved, whether directly in the company or indirectly through their contributions to your life, the more successful your business will be.

Others may have a wide range of opinions about you starting a business. Often successful companies start with people who received lots of criticism at the start, but no business is run alone. Be open to what others have to share with you. Find some people to lean on and keep you accountable, and particularly find some successful business owners to chat with. Whether they’re welders or not makes no difference. The outworking of businesses differs among fields, but the principles remain the same.

How to Start a Welding Business

Your business mindset, financials, and support will never be perfect, but once you have established the right foundation, you’ll be ready to start a welding business. Starting a welding business will obviously require you to have your welding certifications. Once you get some employees, it will be mandatory that they get certified too.

There will come a time where you’ll have to leave your day job and dive into business. This is almost always daunting, but the best way to begin is by gradually easing into it. Don’t just leave your day job and start your business immediately. You’ll have the most success if you start slowly by doing work on the side.

Read 6 Side Gig Jobs for Welders for ideas to start finding work on the side while you’re employed, and ramp your business up from there. Unless you have bucketloads of cash, if you jump in right away, your need to make a full-time income will cloud your view of the best steps forward into a successful welding business.

Once you have some steady work on the side, with the likely prospect of it increasing, try cutting down your hours to work part-time as an employee or contractor, and spend more time on your business. If this isn’t possible, diving full-time into your business is fine, but gradual progression is always healthy when possible.

It isn’t necessary to have all the gear right away. Just having the essentials, to begin with, is fine and often a better way to go. The companies you’ve worked for in the past might be getting a range of customers requiring specific tools. But until you’re established in your company, you won’t know whether you’ll need all the same tools.

For example, maybe your old company had a plasma cutter that was used every day on projects, but no machining equipment. You could buy a plasma cutter expecting the same outcome, but your actual customers may be better served with a small milling machine or lathe instead. Gradually buying all the gear you need will ensure money is spent in vital areas through actual knowledge.

Welding Business Plan and Key Points to Make it Successful

It’s important to have a good foundation before your business is running. Nonetheless, these following points will help ensure that, once your business is established, it flourishes.

These key points are geared towards establishing a welding business that grows and becomes highly lucrative. What you’re after depends on whether you want a small business or a large business. Regardless of your goals, if you embrace these key points, along with the previous principles, you’ll provide excellent service to your customers and make a healthy income for you and your staff.

If you only want a small business, you can simply manage its size by the amount of work and staff you take on, rather than letting it increase by continuing expansions.

Gather satisfied customers

To begin with, you need to start getting customers. Any customer who’s willing to pay a fair price for your service or product is a good customer.

On a rare occasion, you may find a customer has bad intentions, and you can’t do anything about that. Simply serve everyone the same and make sure they pay you accordingly. This will outweigh the negative effect of those few bad customers. Don’t be too particular about who you do jobs for, unless you have sound reasons.

The steps to gain your first customers and those later down the track are the same, but it will be easier when your business establishes its name. The following points will help you have a constant supply of customers.

Tell everyone you know that you’ve started a business

If people know you already, they’re far more likely to support your business than go to an unknown source. They’re also more likely at the beginning stages to choose your company over a stranger, so tell as many friends as you can.

Tell them in person, preferably. Social media pages can work too. If you don’t have social media, it will pay to join some platforms.

Put out quality signs to advertise your services

Gaining customers is all about gaining trust. The more familiar a name is to someone, the more they’ll trust you. Certainly, putting a sign outside your house will encourage a few neighbors to stop by, but the wider you spread quality and captivating signs, the more people will come to trust your business.

Call up local businesses

If there are businesses that would benefit from your fabricated product or that you could serve well with your expertise, call as many of them as you can, and make yourself known. Most companies respect a business owner or respectful representative reaching out in a personal way.

Don’t pester them if they’re not interested. They may get back in touch when the way you treated them comes to mind at a time when they need your service or product. However, if they show interest during your first call, it always helps to do a friendly follow-up and show an interest in their business.

Welding business cards

Get some quality welding business cards and hand them out to potential customers. The more often you can do this in a personal way, face to face, the better. Giving them to customers you’ve served is a great option. Going around to peoples’ houses or businesses, or handing them out at a trade show stall, are also beneficial.

Start a website and build social media presence

It’s essential to have an online presence, unless you’re not concerned about having a successful company. Very few people go for a drive to find a welding shop to use, or some fabricated items to buy; those few who do will be a tiny proportion of the market.

It’s not difficult to get involved on social media. Starting your own website is easy, too. We recommend using WordPress to create yours. It’s free, simple, and offers the most possibilities to develop your site, along with changing it in the future. Some easy tutorials will teach you how to build a WordPress site, including this video version and this thorough article version , which includes video aspects as well.

We recommend hosting your site with Bluehost . It’s affordable, has a great user relationship with WordPress, offers dedicated support, and runs your website faster than many other hosting companies.

Reading guides like etraffic for your website, and Postplanner for your social media presence, will guide you with essential steps to growing your business by advertising your presence in the online market.

Serve your current customers well

Once you have some customers, the best thing you can do for your business is to ensure they’re served well. As Horst Schulze , the co-founder of a multi-billion-dollar company, describes, every customer wants:

- A hassle-free service or product;

- That’s available without time restraints;

- To be delivered by someone in a kind manner.

If you do your very best to provide this to every customer, your company will undoubtedly gain loyal customers who choose your service or products above anyone else’s.

Get quality staff

How do you get quality staff? There are generally plenty of people to choose from, but it’s hard to find excellent staff. You can find employees through:

- Opportunities through business associates

- Leads through local welding shops

- Recommendations by welding schools

- Leads through training centers

- Using hiring agencies

The best way to find quality staff is either by interviewing as many people as you can and judging their skills and character firsthand, or finding someone you trust and who knows exactly what you’re after to interview people. If you go through hiring agencies or use someone who isn’t intimately aware of your vision, you may not find the best candidates.

Once you have some customers and a good team, the kind service customers desire must come from you. It most likely won’t be you serving them, but your staff. They represent you to the customers, because they represent your company. If your employees aren’t happy with the way you treat them, they won’t treat your customers well. There may be the odd excellent employee who will do the job to the utmost regardless of how you treat them, but for the most part, employees display to the customers what you display to them.

When you go above and beyond for your staff, you’ll soon see them going above and beyond for your customers. It also helps to meet regularly with them in an engaging way they appreciate. Go through the company’s vision and personally teach them how to best serve your customers, so they’ll be equipped to do so.

Establishing a self-sustaining company

From the beginning, it is of utmost importance to aim towards a self-sustaining business. Many companies are so heavily dependent upon the few top people running the show that if one or two of them are away, the business cannot function. This is an extremely unhealthy structure.

Bring your staff up to speed with what goes on. Everyone doesn’t need to know everything, but everyone should know how to do their job excellently, and be able to take over someone else’s workload if they’re away. This includes your job. You want a business that will run smoothly, so you can go away and have a vacation or do something else.

My dad’s commercial property was leased to a man who didn’t embrace this principle. He got sick with cancer and died within a few weeks of finding it out. His business shut down immediately, leaving his entire workforce to find new jobs. This is no way to run a business. Instead, employ a self-sustaining model to ensure you have established a successful welding business.

Learn the market and fulfill its needs

Markets are always adapting, some faster than others. Without exception, markets will change in some way a few years after you start your company. Become intimately acquainted with your market. Learn what your customers want, what your competitors are doing, and how to adapt your company to grow accordingly.

If you don’t grow with your market, you’ll be surpassed by someone else. However, be aware that if you progress things too fast, your customers may not be ready for the change. This takes careful strategy, but when executed well, it produces tremendous results for your business.

This principle is not just relevant to big companies. For example, I worked in a small fabricating shop when I first started welding, and my boss didn’t have an EFTPOS machine. For years, customers either set up accounts with the company or paid cash. When EFTPOS came in, many customers expected my boss to have it. To this day, I am not sure if he does. He lost significant opportunities for more and happier customers by this small detail he could have changed easily.

How to Start a Welding Business: In Closing

Learning how to start a welding business is an excellent opportunity for any welder willing to do the hard work of building something amazing. Many people have started average companies that provide them with a bit more income and a small team working for them. But I hope you’re eager to go the extra mile and create a successful, lucrative business with a lasting future.

It may seem like hard work, and it is. But establishing a business properly gives you the support you need to achieve success. You’ll have a great team on your side, customers who are loyal to you and spread the word of your company, and a self-sustaining business that allows you to take vacations without it diminishing.

Feel free to leave your feedback and comments below.

Source and helpful websites:

https://startupcamp.com/sc-blog/

https://forum.millerwelds.com/forum/welding-projects/2135-advice-on-starting-a-welding-business

https://app.aws.org/wj/2001/04/0053/

More Welding Articles Like This:

9 Christmas Welding Projects to Try Today (With Pictures and Videos)

40 Welding Projects for Trucks to Try Today (With Pictures and Videos)

14 Aluminum Welding Projects to Try Today (With Pictures and Videos)

FCAW vs GMAW: Differences, & When to Use Them

How Much Are Welding Salaries in the UK? 2024 Statistics

What is a Typical Welding Salary in Ontario? (2024 Update)

How Much Is A Welding Technician Salary In Canada? (2024 Update)

How Much Are Welding Salaries in Canada? (2024 Update)

Cameron Dekker

Cameron grew up in Allentown, Pennsylvania, a once-proud steel town on the Lehigh River, where he got a taste of TIG welding in his high school shop class. He holds certificates for Certified WeldingEducator (CWE) and Certified Resistance Welding Technician (CRWT) from the American Welding Institute. His interests include scuba diving, sculpture, and kayaking.

Advertisement

Supported by

What to Know About Ukraine’s Cross-Border Assault Into Russia

The incursion caught Russia by surprise and signified a shift in tactics for Kyiv after more than two years of war with Russia.

- Share full article

By Andrew E. Kramer Constant Méheut Kim Barker Anton Troianovski and Cassandra Vinograd

Ukraine pressed ahead with its offensive inside Russian territory on Sunday , pushing toward more villages and towns nearly two weeks into the first significant foreign incursion in Russia since World War II.

But even as the Ukrainian army was advancing in Russia’s western Kursk region, its troops were steadily losing ground on their own territory. The Russian military is now about eight miles from the town of Pokrovsk in eastern Ukraine, according to open-source battlefield maps . The capture of Pokrovsk, a Ukrainian stronghold, would bring Moscow one step closer to its long-held goal of capturing the entire Donetsk region.

That underscored the gamble Ukraine’s army took when it crossed into Russia: throwing its forces into a daring offensive that risked weakening its own positions on the eastern front.

Whether that strategy will prove advantageous remains to be seen, analysts say.

On the political front, the offensive has already had some success: Ukraine’s rapid advance has embarrassed the Kremlin and has altered the narrative of a war in which Kyiv’s forces had been on the back foot for months.

Here’s what to know about Ukraine’s cross-border operation, which President Biden said last week was creating a “real dilemma” for the Russian government.

What happened?

Ukrainian troops and armored vehicles stormed into the Kursk region of western Russia on Aug. 6 , swiftly pushing through Russian defenses and capturing several villages.

Held by Ukraine

as of Aug. 13

Sverdlikovo

Sievierodonetsk

Area controlled

Zaporizhzhia

Sea of Azov

Ukrainian incursion

Source: Institute for the Study of War with American Enterprise Institute’s Critical Threats Project

By Veronica Penney

The assault, prepared in the utmost secrecy , opened a new front in the 30-month war and caught not only Russia off guard: Some Ukrainian soldiers and U.S. officials also said they lacked advance notice.

Analysts and Western officials estimate that Ukraine deployed about 1,000 troops at the start of the incursion. But military analysts say that it has since poured more troops into the operation to try to hold and expand its positions.

How far into Russia have Ukrainian troops advanced?

Gen. Oleksandr Syrsky, Ukraine’s top commander, said last week that his army now controlled more than 80 Russian settlements in the Kursk region, including Sudzha , a town of 6,000 residents. His claims could not be independently verified, although analysts say that Sudzha is highly likely to be under full Ukrainian control.

Ukraine’s advance in the Kursk region has slowed in recent days, according to open-source maps of the battlefield based on combat footage and satellite images, as Russia sends in more reinforcements. The Ukrainian army appears to be trying to dig in along the border area rather than pushing deeper into Russia.

President Volodymyr Zelensky of Ukraine acknowledged that on Saturday, saying : “Now we are reinforcing our positions. The foothold of our presence is getting stronger.”

Why is this significant?

Kyiv has regularly bombarded Russian oil refineries and airfields with drones since Moscow’s full-scale invasion began in February 2022. It has also helped stage two other ground attacks in Russia. Those, however, were smaller forays by Russian exile groups backed by the Ukrainian army, and they ended in quick retreats.

Until two weeks ago, Ukrainian forces had not counterattacked in Russia. The gains in Kursk are the quickest for Ukrainian forces since they reclaimed the Kherson region of their own country in November 2022.

How has the Kremlin responded?

As Ukrainian forces pushed deeper into Russia, Moscow scrambled to shore up its defenses, and President Vladimir V. Putin convened his security services to coordinate a response. The Russian military said it was sending more troops and armored vehicles to try to repel the attack, with Russian television broadcasting images of columns of military trucks.

Military analysts and U.S. officials have said the Russian command had so far brought in reinforcements mainly from within Russia so as to not deplete its units on the Ukrainian battlefield, in what they described as a disorganized effort.

“Russia is still pulling together its reaction,” Gen. Christopher G. Cavoli, NATO’s top military commander, said last week during a talk at the Council on Foreign Relations in New York. He described the Russian response as having been “fairly slow and scattered” as the authorities sorted out which military and security forces should take the lead.

And what about Putin?

The incursion has embarrassed Mr. Putin and his military establishment, prompting questions about Russia’s level of preparedness .

Underscoring how the attack rattled the Kremlin, Mr. Putin lashed out last week at the West in a tense televised meeting with his top officials. “The West is fighting us with the hands of the Ukrainians,” he said, repeating his frequent depiction of the war, which he started, as a proxy campaign against Russia by the West.

Ukraine’s incursion has brought the war into Russia like it never has before, and tens of thousands of civilians have evacuated the border area.

What is the goal of Ukraine’s incursion?

Analysts say that Ukraine’s offensive has two main aims : to draw Russian forces from the front lines in eastern Ukraine and to seize territory that could serve as a bargaining chip in future peace talks.

Mykhailo Podolyak, a top Ukrainian presidential adviser, said last week that Russia would be forced to the negotiating table only through suffering “significant tactical defeats.”

“In the Kursk region, we can clearly see how the military tool is being used objectively to persuade” Russia to enter “a fair negotiation process,” he wrote on social media .

The operation has offered a much-needed morale boost for Ukrainians, whose forces have been losing ground to Russian troops for months.

But military analysts have questioned whether Kyiv’s cross-border assault is worth the risk, given that Ukrainian forces are already stretched on the front lines of their own country.

How is it affecting the fight inside Ukraine?

Russian forces have been pummeling Ukrainian troops in the east even as Moscow races to respond to the incursion into Kursk , according to analysts, Western officials and Ukrainian soldiers.

Russia has begun to withdraw small numbers of troops from Ukraine, they said, to try to help repel the Ukrainians, but not enough to significantly affect the overall battlefield for now.

Senior American officials have said privately that they understood Kyiv’s need to change the narrative of the war, but that they were skeptical that Ukraine could hold the territory long enough to force Russia to divert significant resources from the front lines in eastern and southern Ukraine.

While Kyiv’s allies have in the past been wary that Ukrainian incursions in Russia could escalate the war, the European Union’s top diplomat, Josep Borrell Fontelles, said last week that Ukraine had the bloc’s “ full support .”

Ukraine has used some Western-supplied weapons in the Kursk operation. But so far, the United States and Britain, two of Kyiv’s closes allies, have said the incursion did not violate their policies.”

What happens next?

As the Ukrainian offensive approaches its two-week mark, analysts say that Kyiv has several options, each with its own challenges.

Ukrainian forces could try to keep pushing farther into Russia, but that will become harder as Russian reinforcements arrive and Ukraine’s supply lines are stretched.

They could keep digging into the territory they now hold and try to defend it, but that could expose fixed Ukrainian positions to potentially devastating Russian airstrikes.

Or, battered by continual losses in eastern Ukraine, they could decide that they have made their point and pull back.

Thibault Fouillet, the deputy director of the Institute for Strategic and Defense Studies, a French research center, said Ukraine’s next move would depend on how Russia responds. “The coming week will be decisive,” he said.

Eric Schmitt contributed reporting.

Andrew E. Kramer is the Kyiv bureau chief for The Times, who has been covering the war in Ukraine since 2014. More about Andrew E. Kramer

Constant Méheut reports on the war in Ukraine, including battlefield developments, attacks on civilian centers and how the war is affecting its people. More about Constant Méheut

Kim Barker is a Times reporter writing in-depth stories about national issues. More about Kim Barker

Anton Troianovski is the Moscow bureau chief for The Times. He writes about Russia, Eastern Europe, the Caucasus and Central Asia. More about Anton Troianovski

IMAGES

COMMENTS

This is a behind the scenes shop tour of the fabrication shop (metal shop) that I film most of my videos in. I get a lot of questions about the shop so I fig...

Cannon Builder requested a shop layout and shop tour video, so figured I would make one. Just showing my thougths on welding shop, or fab shop, or any work ...

Thanks for watching For more content follow @amcustomfab Or on Instagram @ amcustomfab Find my welders at Primeweld.comAffiliate links CNC Plasma table li...

Welding Workshop Layouts. ... Small Auto Shop Garage Tour. This shop features a well-organized and efficiently designed workspace. It includes an insulated garage with heating, cooling, and insulation to ensure a comfortable working environment throughout the year. The garage boasts a sub-panel for ample electrical supply, an extensive lighting ...

Shop Tour! ⚡️Not sure what to expect from a welding shop? Check out a virtual tour of our office and shop located in the heart of historic Williamsburg, VA! . . . #weld #welding #williamsburgva...

A quick video I did on my "starter" home welding shop. Let me know if you have suggestions for improvements! David Thiel. Crafting, DIY, Industrial Arts, Welding. welding, home welding shop, welding shop tour, weld shop tour, metalwork, mig welding shop, beginner welder. Facebook 0 Twitter Pinterest 0 0 Likes.

An architect can provide you with an initial drawing for the shop layout. Use a copy of the cut-to-scale drawings to sketch in people. Mentally walk through activities and imagine people in the space and how they will use it. Doing so will help you design a space optimized for productivity and efficiency.

You can see a tour of my home welding shop here. Millermatic 215 Welder This is the welder I use, and it falls into the "buy once, cry once" category because of its cost… but it works on 110 and 220, it does stick, mig, and tig welding, and it welds materials up to a half inch in thickness.

Welderup is a complete custom fabrication shop specializing in one-of-a-kind vehicles located in Las Vegas, NV. ... Welding Workshops ... Experience Steve's distinctive brand of rat rod culture firsthand and at your convenience on a self-guided tour of the new WelderUp showroom and store.

20 questions with answers for Welders: FAQS. Welding is a skilled trade that involves joining two or more metal pieces together using heat, pressure, or a filler material. It is a critical process that is used in many industries, including construction, manufacturing, and repair and maintenance. To help you understand the basics of welding, we ...

Start to Finish building an Arctic Snow Pusher from raw Steel & materials. It used to take them 2 weeks to Build one Arctic Pusher. Now they make one every H...

Shop tour!#wisconsin #fabricationshop #workforyourself #tools #welding #shoptools #shoptour #chiassonsmoke #welding #fabricationshop #diyproject #bluecollar #fabricationshop #welding #diyproject...

Sustainable growth ensures your welding shop can weather economic downturns, respond to evolving industry trends, and maintain a reputable presence in the industry. By securing your space, recognizing competition, professionalizing early, and focusing on sustainable growth, your shop will be well positioned to find independent success in the ...

welding, history | 16K views, 1.1K likes, 98 loves, 79 comments, 23 shares, Facebook Watch Videos from Laura Farms: Touring a unique welding shop with history ♂️

Start a website and build social media presence. It's essential to have an online presence, unless you're not concerned about having a successful company. Very few people go for a drive to find a welding shop to use, or some fabricated items to buy; those few who do will be a tiny proportion of the market.

Behind the scenes inside the CMP attachments shop during its rapid growth. How Andrew managed it from 480,000 a year to over 4 million a year in products g...

Top Kursk Horseback Riding Tours: See reviews and photos of Horseback Riding Tours in Kursk, Russia on Tripadvisor.

This interactive time-lapse complements static control-of-terrain maps that ISW produces by showing a dynamic frontline.

You were asking for a quick shop tour. Let me show you around the welding shop. Still a work in progress but it's getting there.#chiassonsmoke #fabrication #diyprojects #welding. Guns N' Roses ·...

CHECK OUT THE GARAGE SHOP TOUR! ENJOYWELDING LENS I USE -https://www.rod-shield.com/s/shopSAVE 5% PROMO CODE - MCFWELD Wanna send me something?MCF WELDING95 ...

Ukrainian servicemen drive Soviet-made T-64 tanks in the Sumy region, near the border with Russia, on August 11, 2024. Russia acknowledged Ukrainian troops had pierced deep into the Kursk border ...

Since my not to put together truck didn't run you off I thought today we could do a little welding shop tour! My garage welding shop isn't fancy but it conti...

Aug. 18, 2024. Ukraine pressed ahead with its offensive inside Russian territory on Sunday, pushing toward more villages and towns nearly two weeks into the first significant foreign incursion in ...